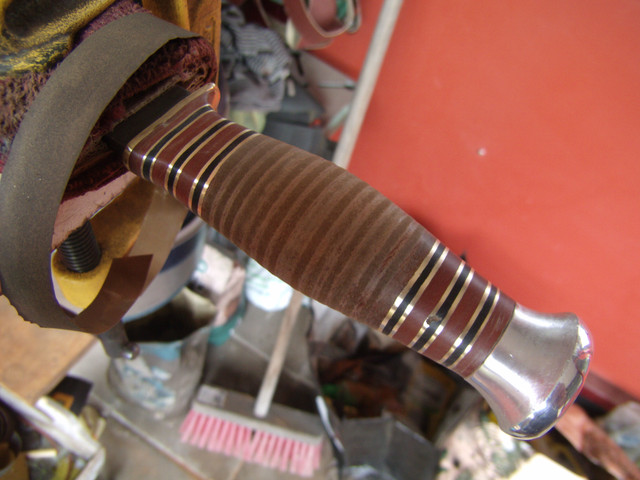

Recently acquired these two fixed blades made by Swedish manufacturer Pontus Holmberg.

According to this website the model was once used as a survival knife for the Swedish Air Force: http://www.gotavapen.se/gota/artiklar/knivar/aforce/1survival.htm

I'm in the process of giving each one a bit of TLC, and will post some pics later on.

According to this website the model was once used as a survival knife for the Swedish Air Force: http://www.gotavapen.se/gota/artiklar/knivar/aforce/1survival.htm

I'm in the process of giving each one a bit of TLC, and will post some pics later on.